സ്പ്രേ ബോട്ടിലിനായി 30 - 100 എംഎൽ പെർഫ്യൂം ഫില്ലിംഗ് മെഷീൻ

Perfume and Essential Oil Filling Solutions

Whether you have glass or plastic perfume bottles,cor whether they have spray caps - we have all the equipment needed to bottle fragrances, deodorants, essential oils or aftershave

From homemade production to professional and industrial applications: we have a great number of solutions to bottle fragrances, aftershave, essential oils, and other perfumed alcohol solutions. Our machines are known for their simplicity, speed of use and are easy to clean. But above all, our machines are resistant and made of high quality materials in order to fill any kind of fragranced product and are incredibly accurate and do not waste product. These are the main characteristics of our machines, suitable and studied to fill perfume.

automatic low vacuum filling, auto bottle detecting ( no bottle no filling), filling for three times,auto dropping of spray head cap, circulation of perfume bottles’ die set, it is wide adaptability which can meet to the requirements of different dimension and filling volume of containers.

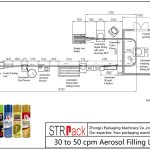

It is equiped with air cleaning for bottles, quantitive filling, negative pressure filling, pump placing , lid rolling, jacket placing ,capping,rejecting, labeling and end product collecting etc. Moulds move in circles, easy to change bottles;Stepping motor for quantitive filling, fast to adjust filling volume;Negative pressure device is used to fill in the same liquid level;Manipulator for pump placing and pre-rolling is applied to increase pump rolling rate; Elastic rolling head is to avoid the bottle body from damage.

It is equiped with air cleaning for bottles, quantitive filling, negative pressure filling, pump placing , lid rolling, jacket placing ,capping,rejecting, labeling and end product collecting etc. Moulds move in circles, easy to change bottles;Stepping motor for quantitive filling, fast to adjust filling volume;Negative pressure device is used to fill in the same liquid level;Manipulator for pump placing and pre-rolling is applied to increase pump rolling rate; Elastic rolling head is to avoid the bottle body from damage.

Machine Specification

Filling volume: 5~120ml

Filling speed: 30-50bottles/min

Filling accuracy: ≤±1%

Finish products rate of cap dropping and locking: ≥99%

Main machine power: 1KW 220/380 V frequency control